How is Spray Finishing Done?

Spray painting is commonly known as Factory applied finish or Lacquering. Spray paint is applied to

material using high pressure air, mixed with paint particles, allowing to achieve consistent and smooth

finish throughout the material. The difference between traditional brush painting and spray finishing -

No BRUSH Marks. Spray paints are more durable and provides even coating on any surface whether it is

flat board or moulded panel, all surfaces will receive even amount of paint layer.

We offer Online Spray Finishing facility for your convenience while creating

Cut To Size project or Spray Finishing only for project you have been creating at home. This is where

Online Spray finishing option comes in handy, you can type in the dimensions of your part and we will provide

you with an Instant Online Quote. We spray all types of materials, but have limited spraying options depending on material type.

Within the online portal you can choose the type of finish you require including any colour from all major paint

manufacturers or you can provide us with your own sample which we will match. Touch up paint supplied

with every spray job.

Pricing: If your part is less than 0.25 m2 we will calculate it as being 0.25 m2 as a minimum spray finishing area.

How We Do It?

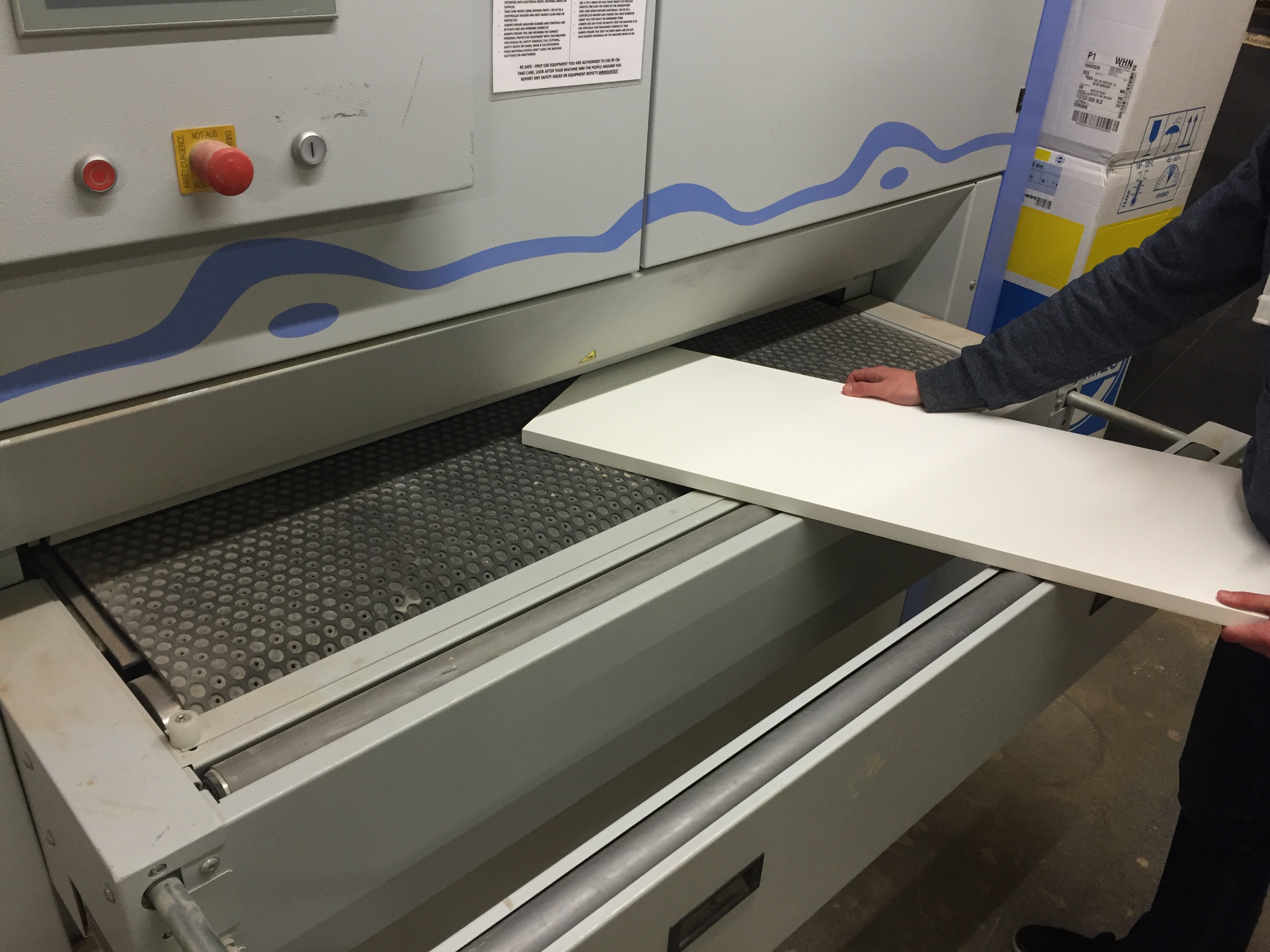

All parts before receiving any type of coating need to undergo preparation process. This involves edge banding as well as preparation sanding. We have latest in Technology Wide belt sander which allows us to calibrate and finish sand all parts before applying primers or clear lacquers. Calibration of parts eliminates any surface imperfections. After priming or base lacquering all parts are being sanded again to receive final coats of spray paint or clear lacquers. High gloss finish requires burnishing. This is quite lengthy process but the results are perfection of Mirror effect gloss.

Spray Types & Sheene Levels

Primer Exterior

Exterior Primer is use for materials to be exposed to Exterior conditions or in high moisture concentration areas. We use Exterior Micro Porous Primer which is water based material designed to allow material to breath but does not allow the moisture to penetrate the material.

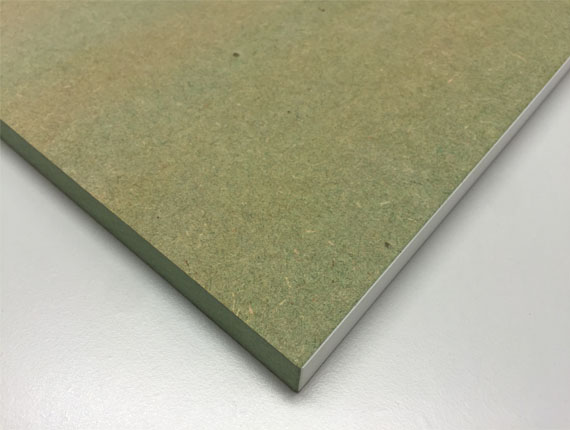

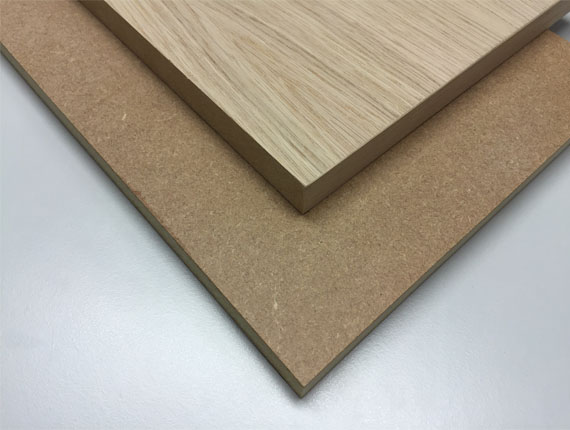

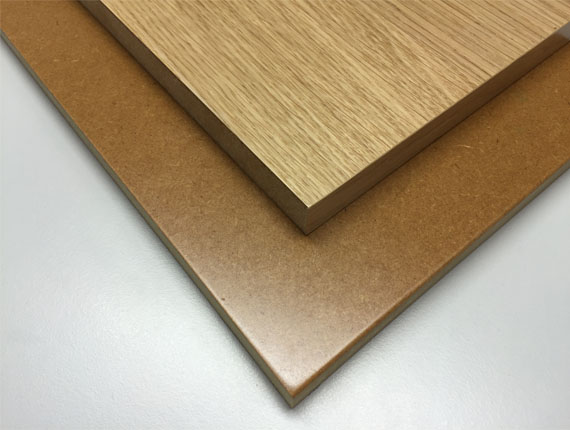

Primer Interior

Interior primer is designed for dry interior conditions. We use PU (Polyurethane) high build up primer which is ideal for MDF and all other materials. Once edges are sealed with this primer, wood fibres are sealed and further coats of paint do not get soaked. Single Coat of paint will be enough for final coating.

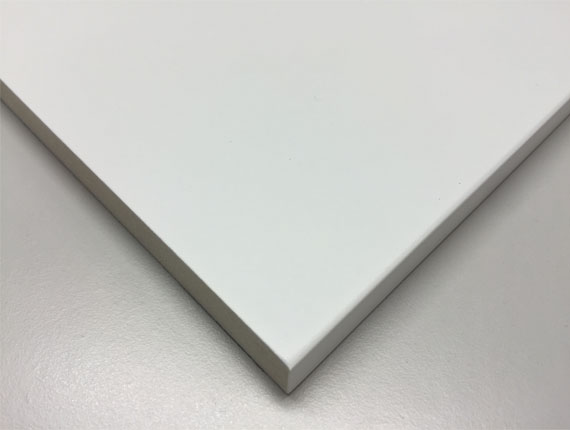

Paint

Shine Levels are normally measured by percentage using spray paints. We use Polyurethane paints for finishes from 10% up to 50% Sheen. Polyester coatings used for High gloss finishes. We can mix any colour by A Code of any Paint Manufacturer or we can match your samples.

Paint Exterior

This type of paint can be used on MDF Tricoya or any kind of wood based joinery. We can match any colour from any Paint Manufacturer by a code or by scanning the colour. In order to scan the colour we need clean sample for accurate scan. Max Sheen Levels on Micro Porous Paint is 60%. If Gloss finish is required alternative paint types will be used.

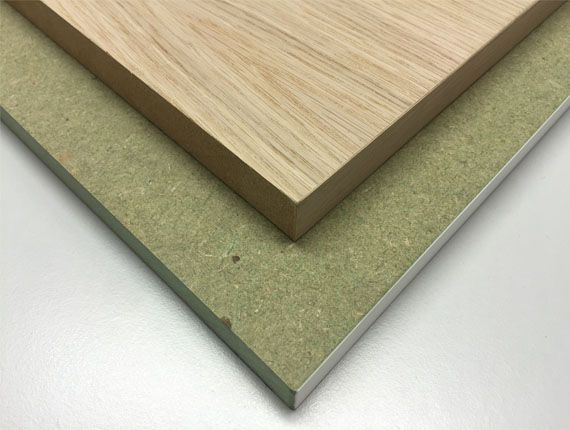

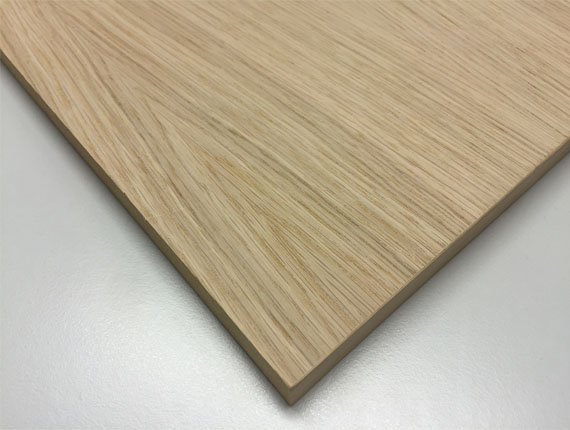

Clear Lacquer

Clear lacquer is used when natural material is required to be seen with protective coating from environmental conditions and to enhance beauty of natural wood fibres. We use Clear Lacquer for sealing MDF, Birch Plywood, Valchromat and many more types of material. Finishes available from dead matt to high gloss finish.

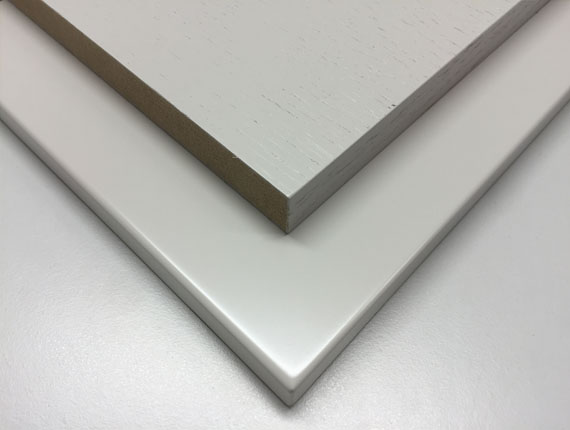

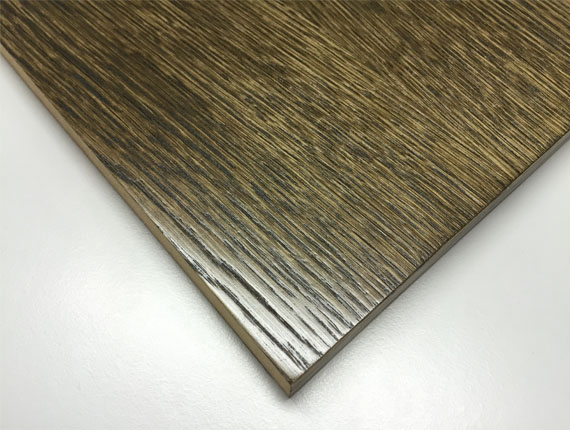

Staining

Stain is normally used to enhance wood grains, change the colour of the wood while showing its natural beauty. Options of stains are endless. We offer only a few on our website or we can offer matching service by request. For special Projects please contact us for Quote.

| Sheen Levels | |

|---|---|

| Matt | 10% |

| Satin | 30% |

| Eggshell | 50% |

| Gloss | 100% |